Monday 19th June 2006.

Steve 2 undercoated the engine room, with dark grey at the bottom and cream at the top.I climbed into my overalls (sexy huh) to finish painting the mast and the cratch with Mauritius Blue Gloss, I really love that colour. The Red Oxide Enamel and the Mauritius Blue will be the final colours, but they will be rubbed down and reapplied when "HADAR" has her final paint job, and that will be done by Tina Paramore after "HADAR's" fit out which comes next.Roger and Keith unpacked the sheeting and set about putting the side sheets up in the open hold, firstly they checked that they were the right length, they then laid a black mastic strip along the metal fixing strip the length of the open hold. They began to lay the side cover over the mastic strip and then battened them into place with oak battens, which were screwed to the metal work of the open hold. So we had a sandwich, metal fixing strip, mastic strip, side sheet and then oak batten all screwed together. Not the sort of sandwich you would want to eat though LOL.Having completed both starboard and port side sheets as far as they could go, they put the newly painted stand and planks into place.

Tuesday 20th June.

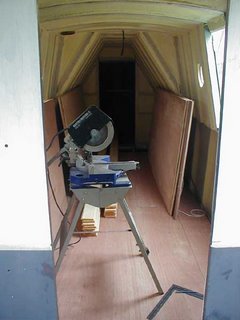

Roger and Keith finished fitting the side sheets over the saloon. They were a little more difficult to fit. After they were in place the painted Mast, cratch and remaining planks were put up. The side sheets were roped into place over the planking with blue nylon rope for now, it will be replaced before we take "HADAR" away. The top sheets were rolled out, and placed over the top planks along the open hold and over the saloon, checking all three sheets to make sure the eyelets matched up with the fixing loops on the gunwales. It all looked fantastic, and fitted perfectly. Keith sat down and made eye splices to tie the top sheets into place. Once they were tied into place we roped the top sheets down. Standing back and looking at her all done, already for launching, bought a lump to my throat, because this was the day we had been waiting for. She is all ready for launching.

Wednesday 21st June.

Roger and Joel (on work experience) started to move "HADAR" across to the centre of the shed ready for her launch on Thursday. All this was done with the use of rollers, a dumper truck and brute force. It took pretty much the whole day to get her in the right place.

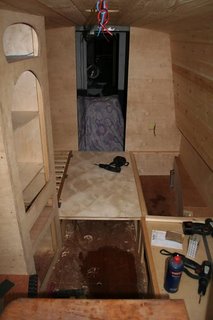

The upper walls of the saloon and the first part of the galley have now been fitted. It is taking shape rather nicely. Despite the sloping roof of the 8 ft saloon there is plenty of headroom. Well there is for Keith and I as we are both short!

The upper walls of the saloon and the first part of the galley have now been fitted. It is taking shape rather nicely. Despite the sloping roof of the 8 ft saloon there is plenty of headroom. Well there is for Keith and I as we are both short!

Roger then went onto make the wooden hatch slide, which was then covered in aluminium, and an aluminium strip screwed around the edge.

Roger then went onto make the wooden hatch slide, which was then covered in aluminium, and an aluminium strip screwed around the edge.

Then the walls were lined out with plywood and edging strips for that final detail. The whole thing looks fabulous.

Then the walls were lined out with plywood and edging strips for that final detail. The whole thing looks fabulous.

The beginings of the ticket draw have begun with the frame work.

The beginings of the ticket draw have begun with the frame work.

Then the lining out of the other wall began with hardboard, to this the bed and cupboard will be fitted, and there are of course wires dangling ready for connecting up when the time comes.

Then the lining out of the other wall began with hardboard, to this the bed and cupboard will be fitted, and there are of course wires dangling ready for connecting up when the time comes. It has actually got exciting seeing her boatmans cabin begin to come to life.

It has actually got exciting seeing her boatmans cabin begin to come to life. The Hardwood Step went in and it really is a solid piece of wood. I have no idea what sort of hardwood it is, but it looks the part anyway and will definately see alot of footprints on it over the years to come.

The Hardwood Step went in and it really is a solid piece of wood. I have no idea what sort of hardwood it is, but it looks the part anyway and will definately see alot of footprints on it over the years to come. See what I mean, it is a substantial piece of wood.

See what I mean, it is a substantial piece of wood.

The beginings of the boatmans cabin cupboard shell have gone in. So a very busy week with the fit out. Both Keith and I really enjoy taking in all that is going on, we will definately know where every wire and screw is by the end of this journey.

The beginings of the boatmans cabin cupboard shell have gone in. So a very busy week with the fit out. Both Keith and I really enjoy taking in all that is going on, we will definately know where every wire and screw is by the end of this journey.

The answer was to build 2 ramps up out of wood and steel plate to shift these rollers back behind the pivot point, this took quite a while as Roger wanted to be certain that she would roll down them without breaking the ramps, or falling off them! But once he was satified with the setup, the boats moored in the basin were all tied together and then drifted out of the basin across the canal out of harms way. A large piece of wood about the size of a railway sleeper was tied against the opposite bank where it was expected for her to strike the wall. Roger then gave me the go ahead to name her, which I did, " I name this boat HADARm godbless her and all who sail in her" accompanied by the mandatory bottle of champagne.

The answer was to build 2 ramps up out of wood and steel plate to shift these rollers back behind the pivot point, this took quite a while as Roger wanted to be certain that she would roll down them without breaking the ramps, or falling off them! But once he was satified with the setup, the boats moored in the basin were all tied together and then drifted out of the basin across the canal out of harms way. A large piece of wood about the size of a railway sleeper was tied against the opposite bank where it was expected for her to strike the wall. Roger then gave me the go ahead to name her, which I did, " I name this boat HADARm godbless her and all who sail in her" accompanied by the mandatory bottle of champagne.

We just could not finish the day without a photograph of us with Roger Fuller and our new boat "HADAR".

We just could not finish the day without a photograph of us with Roger Fuller and our new boat "HADAR".